Product search

Brands

Select brand

- Kaikki

- Adev

- ADZ NAGANO

- Aquametro

- Badger

- Banner

- Bauer Kompressoren

- Blackline Safety

- BOGE

- Classic Filters

- Codel

- Crane

- Delta Mobrey

- Detector

- Dias Infrared Systems

- Donaldson

- Dostmann

- Effecto

- EKS

- Elindco

- Emerson

- Escha

- Finetek

- Fitok

- Fortress

- FST GmbH

- Hanwha Techwin

- Hertz Kompressoren

- Honeywell

- Houdec

- Iconics

- Idem Safety

- IPR

- LASE

- Limatherm Sensor

- Lumasense

- Marsh Bellofram

- MB Connect Line

- MesaLabs

- Microsyst

- Mobotix

- Monitor

- Motrona

- Nexcom

- Optex

- Parker

- PST

- Red Lion

- Scaime

- SEG

- Seneca

- Senmatic

- SpotSee

- TURCK

- VPInstruments

- Watlow

- Zander Aachen

- Zimmerli Inert

Automation and digital solutions

- Sensors and cables

- Instrumentation and analysis

- IIoT

- Gas detectors

- Display and signaling devices

- Control and data transfer

- Robotics and machine vision

- Safety

Compressed air

Temperature Sensors with Protective Tubes

Temperature sensors with ceramic or fire-resistant chrome tubes for processes above 1000°C. Pocket-type sensors for process industries.

Temperature Sensors with Ceramic Protection Tubes

Temperature sensors with ceramic protection tubes are used in furnaces, heat treatment, and industrial processes where temperatures exceed 1200 c.

- Ceramic sensors generally use noble metal elements, such as Platinum-Rhodium elements of types S, R, and B.

- The sensor can also be equipped with a Type K sensor, with a maximum temperature of 1300 c.

- The ceramic sensor is often equipped with a double tube, where one tube is gas-tight.

- The advantage of ceramic sensors is their excellent heat resistance and durability against mechanical and aggressive wear.

- Mechanical shocks and installation-related impacts can easily damage the sensor.

- Rapid temperature changes may also break the sensor, so preheating the sensors in fast processes is recommended.

Temperature Sensors with Heat-Resistant Steel Tubes

Temperature sensors with fire-resistant chrome tubes are used in boilers, furnaces, heat treatment, and industrial processes where temperatures exceed 1000 c.

- Available in different alloy materials depending on the process contents; e.g., SO2 and N2 concentrations require different materials.

- In some cases, tubes need to be coated for improved durability, e.g., by enameling.

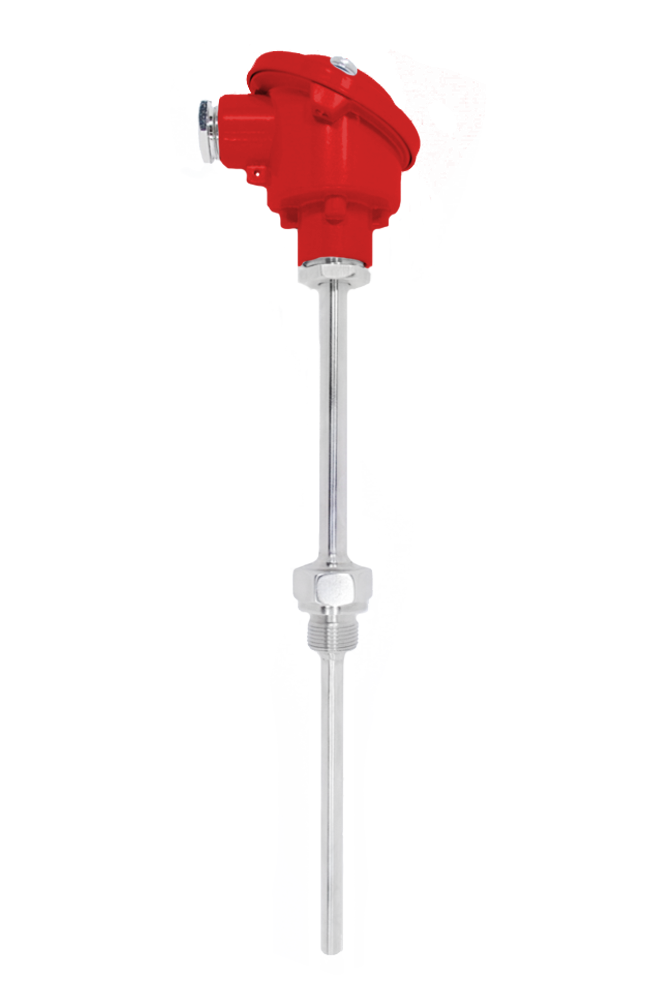

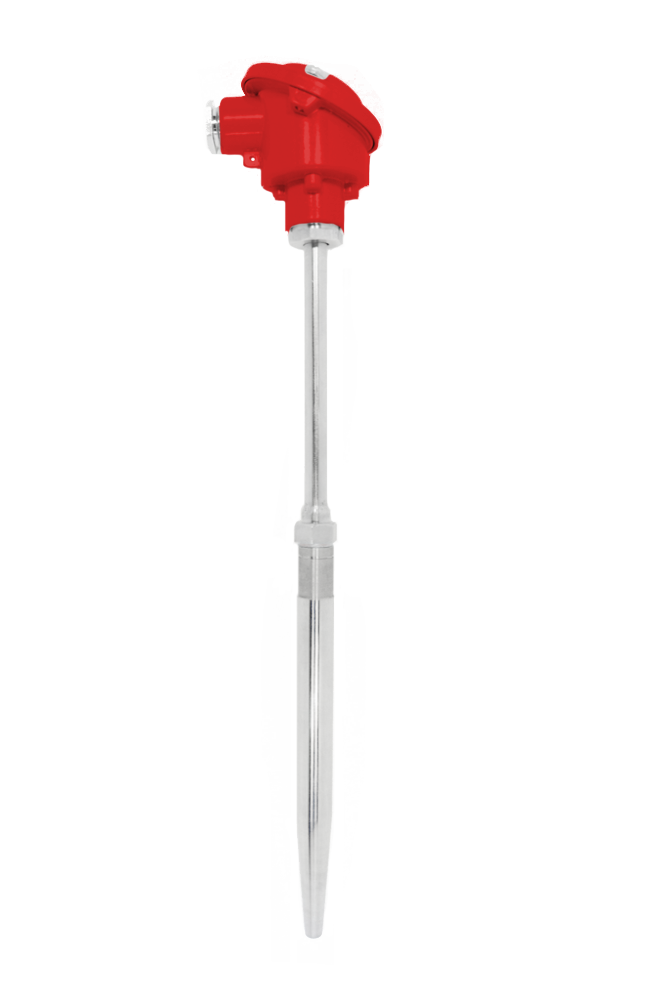

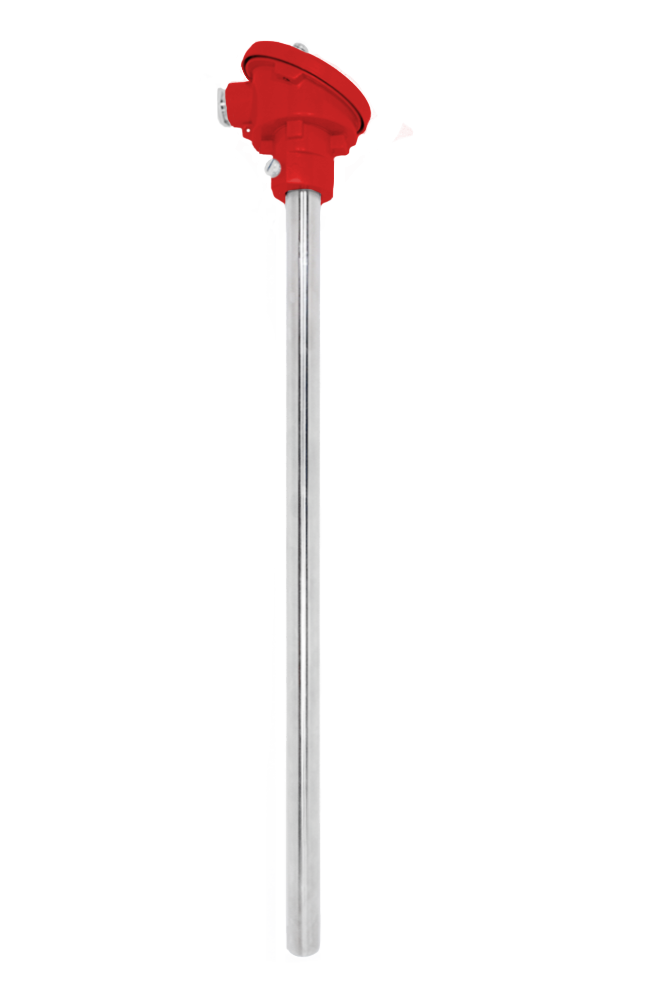

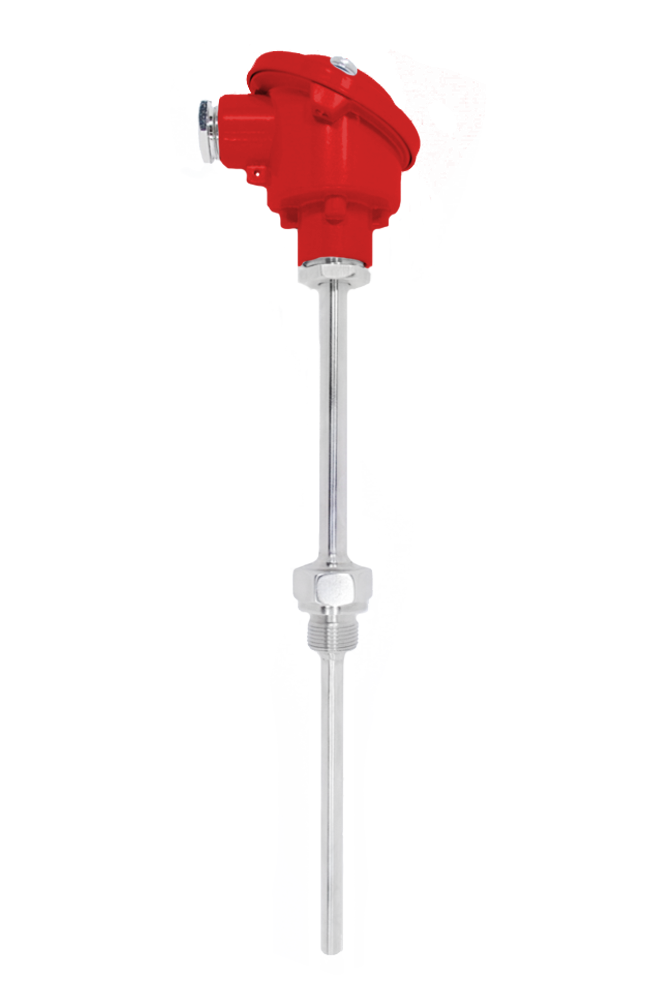

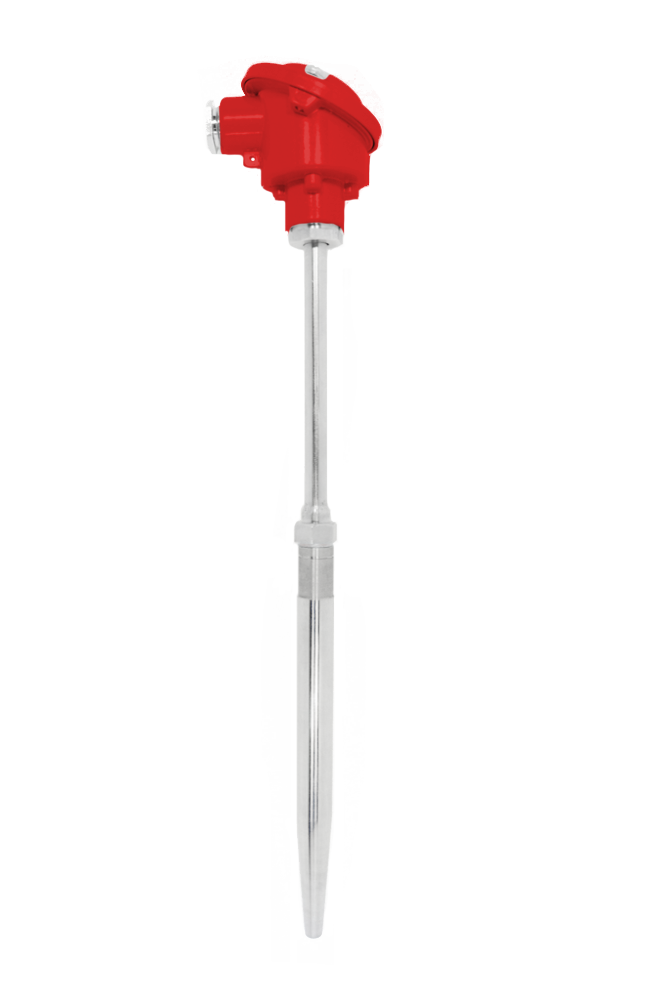

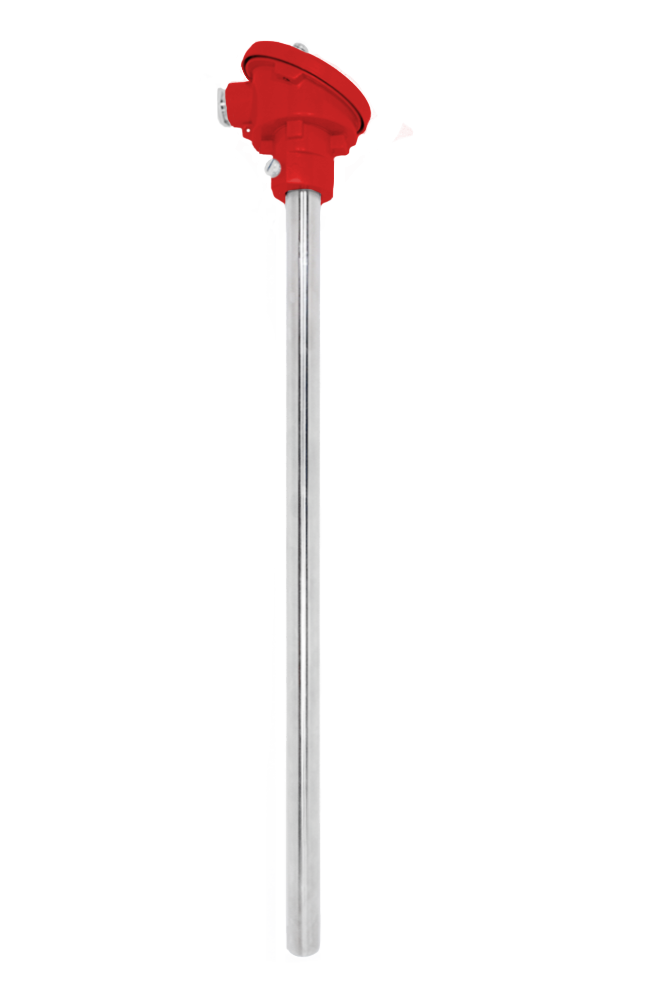

Thermowell Sensors

Process industry sensors with threaded, flanged, or welded thermowells.

- Dimensions according to DIN standards or customer order.

- Thermowell materials according to process requirements.

- Equipped with Pt100 or thermocouple sheath element.

- If necessary, a housing transmitter can be installed in the sensor.