Product search

Brands

- Kaikki

- Adev

- ADZ NAGANO

- Aquametro

- Badger

- Banner

- Bauer Kompressoren

- Blackline Safety

- BOGE

- Classic Filters

- Codel

- Crane

- Delta Mobrey

- Detector

- Dias Infrared Systems

- Donaldson

- Dostmann

- Effecto

- EKS

- Elindco

- Emerson

- Escha

- Finetek

- Fitok

- Fortress

- FST GmbH

- Hanwha Techwin

- Hertz Kompressoren

- Honeywell

- Houdec

- Iconics

- Idem Safety

- IPR

- LASE

- Limatherm Sensor

- Lumasense

- Marsh Bellofram

- MB Connect Line

- MesaLabs

- Microsyst

- Mobotix

- Monitor

- Motrona

- Nexcom

- Optex

- Parker

- PST

- Red Lion

- Scaime

- SEG

- Seneca

- Senmatic

- SpotSee

- TURCK

- VPInstruments

- Watlow

- Zander Aachen

- Zimmerli Inert

Automation and digital solutions

- Sensors and cables

- Instrumentation and analysis

- IIoT

- Gas detectors

- Display and signaling devices

- Control and data transfer

- Robotics and machine vision

- Safety

Compressed air

Robot Tool Changers

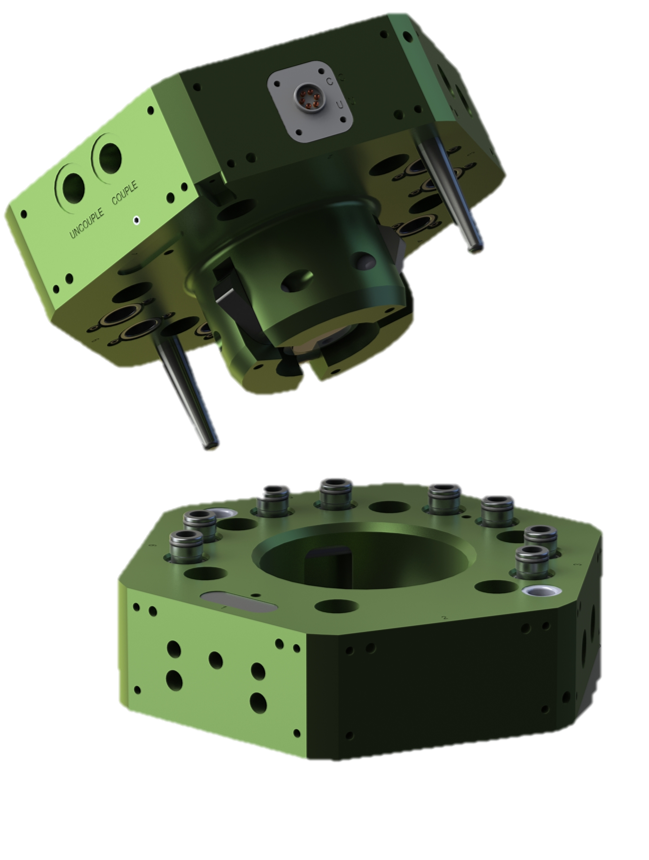

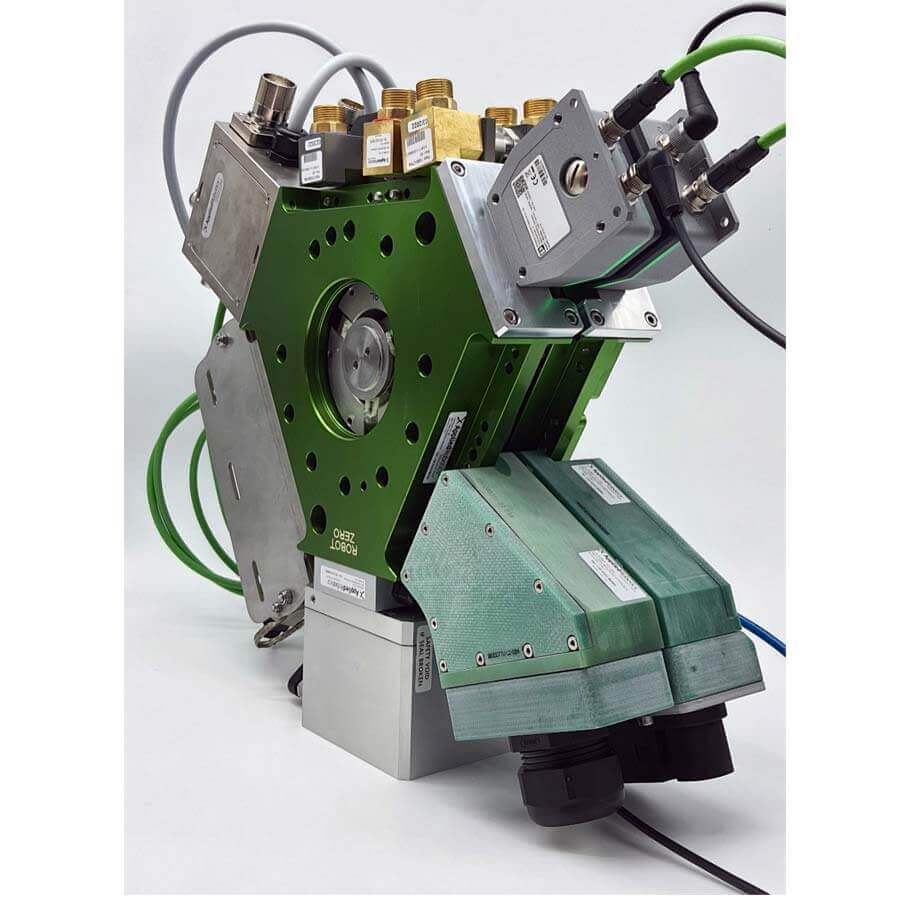

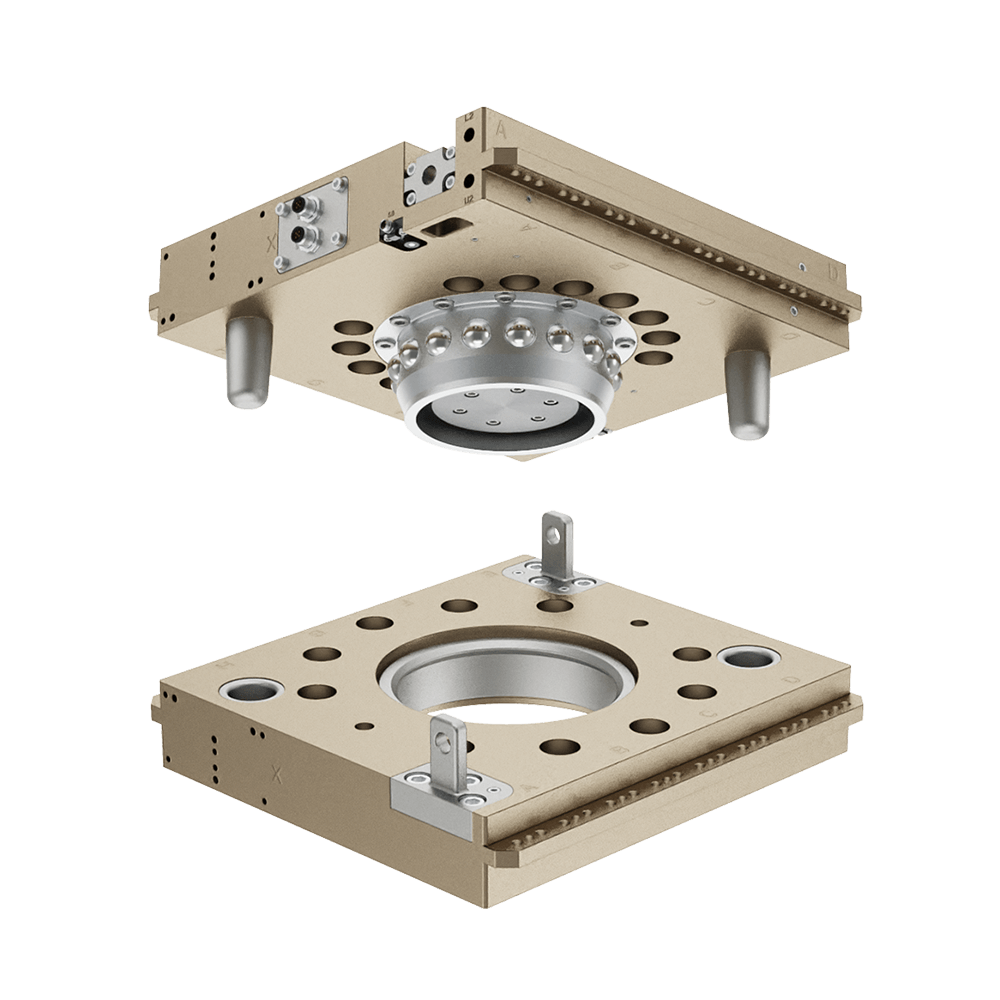

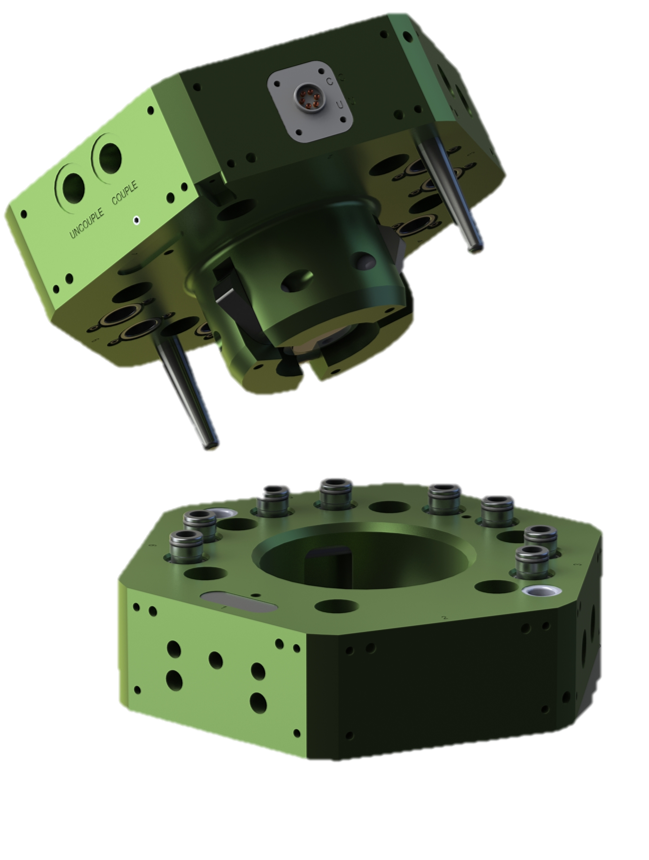

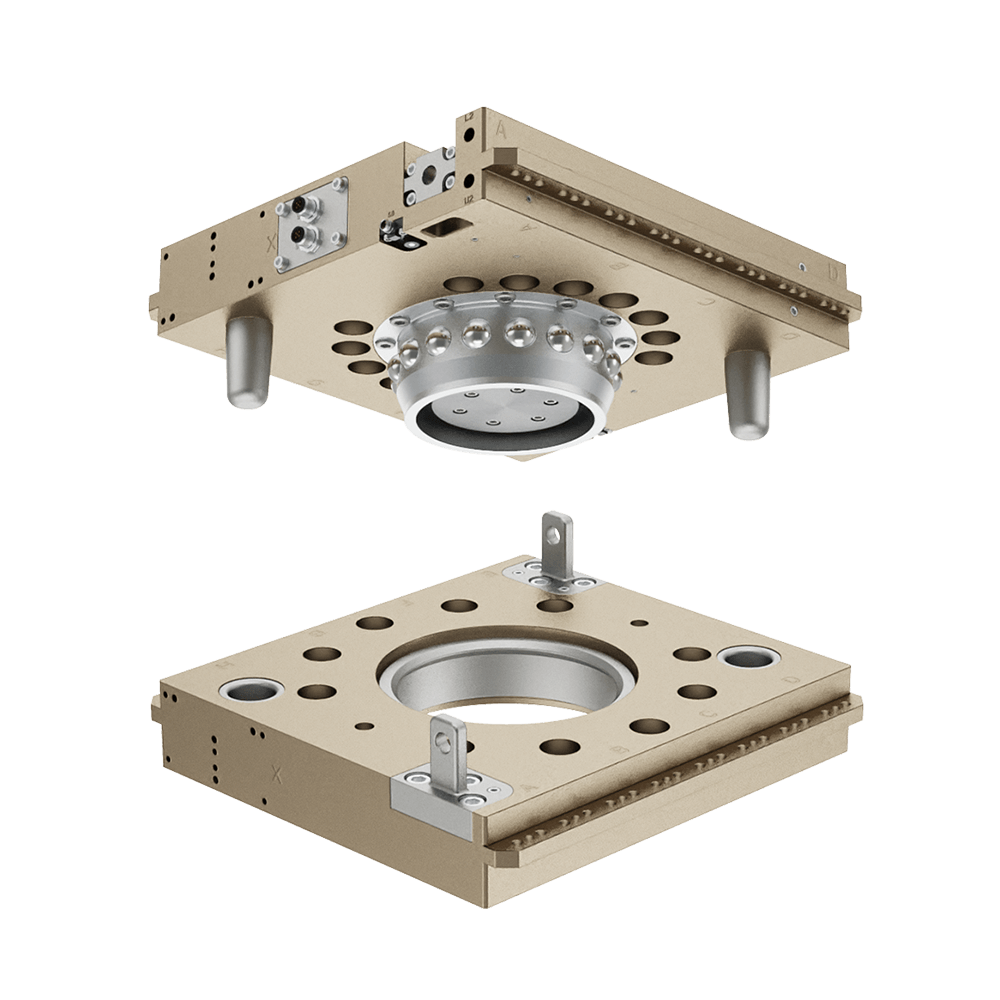

With a tool changer, robots can easily and accurately switch between different tools. Tool changers are available in both manual and automatic versions. Manual changers are designed for loads up to approximately 50 kg, while automatic changers can handle up to 2300 kg. In addition to mass, it is essential to consider the moments applied to the changer, especially during emergency stop situations, and how the robot is operated and in what type of process.

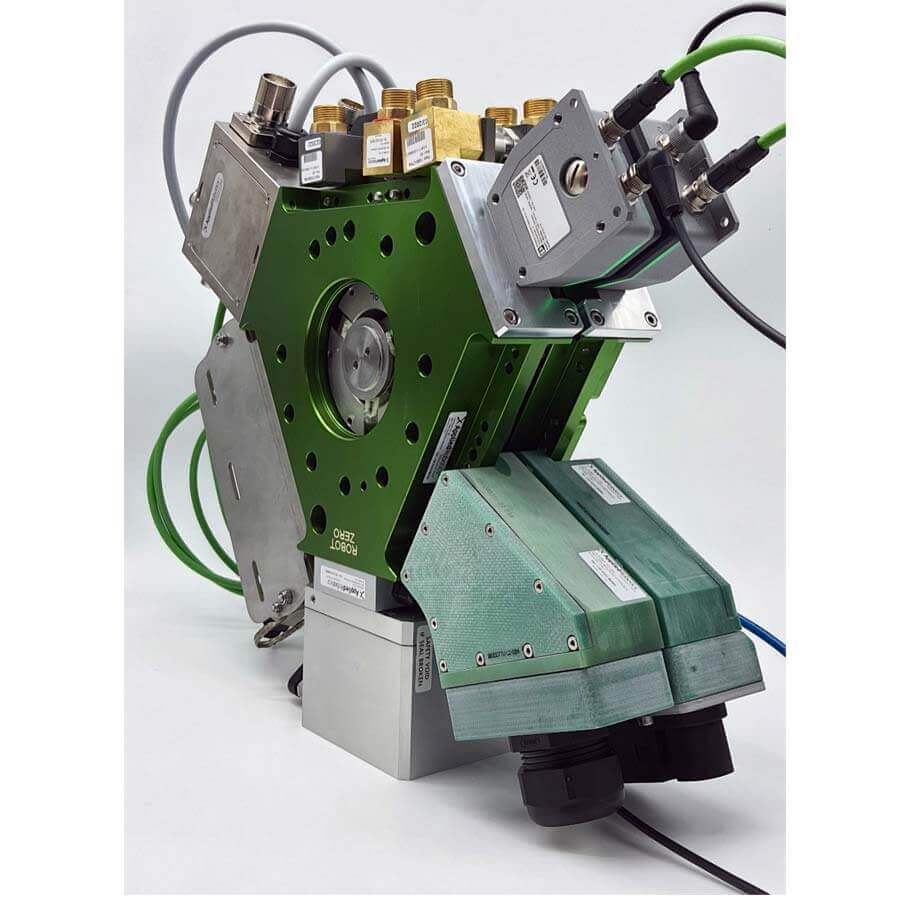

With an automatic changer, the robot can independently switch tools and retrieve or deliver required tools from a tool stand. When selecting a tool changer, it is important to consider its reliability, safety, ease of use, and the range of passthrough modules available. Required passthroughs can include, for example, compressed air, various sensor signals and bus systems, hydraulics and cooling fluids, welding currents and grounding, camera signals, etc.

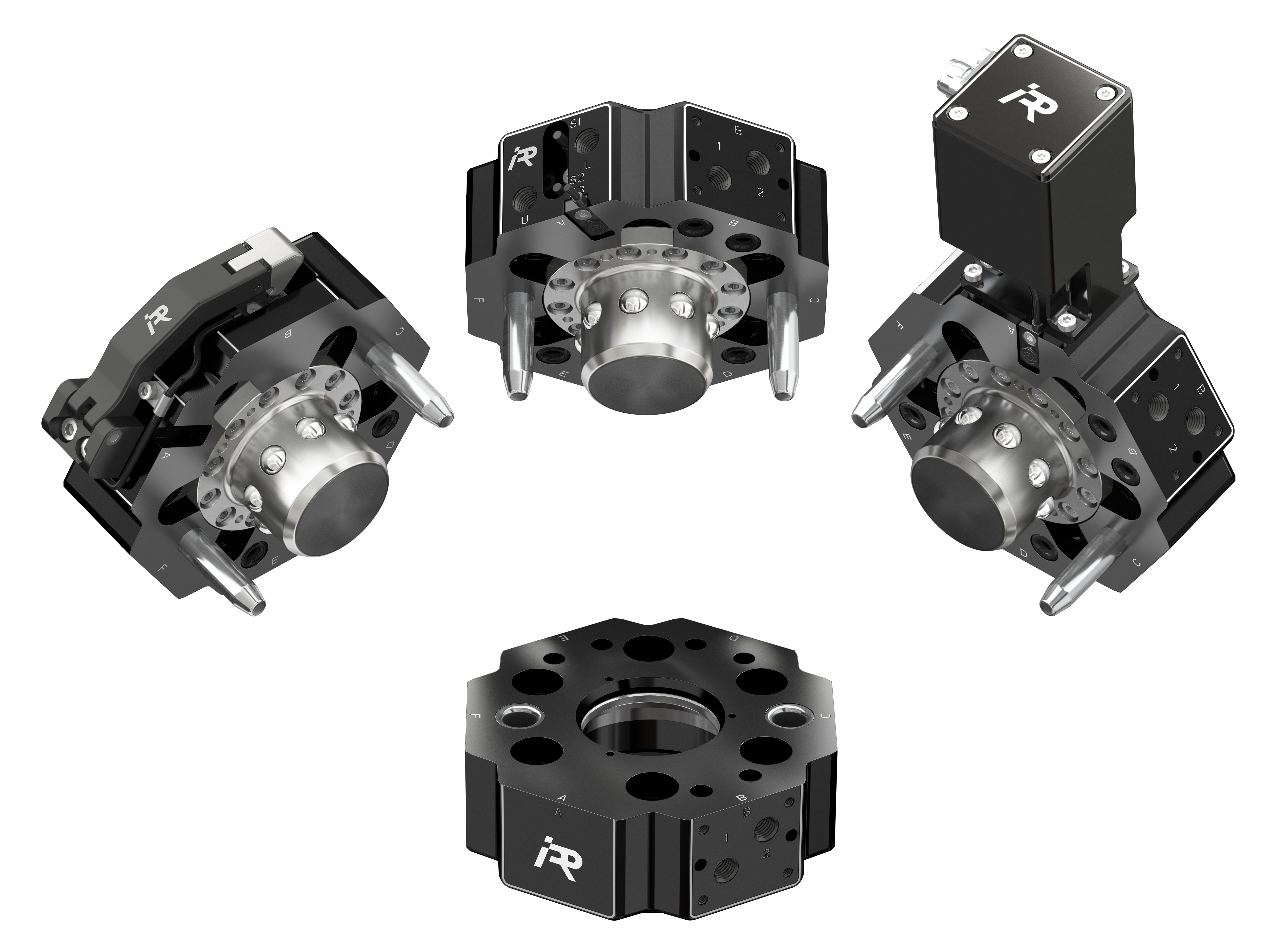

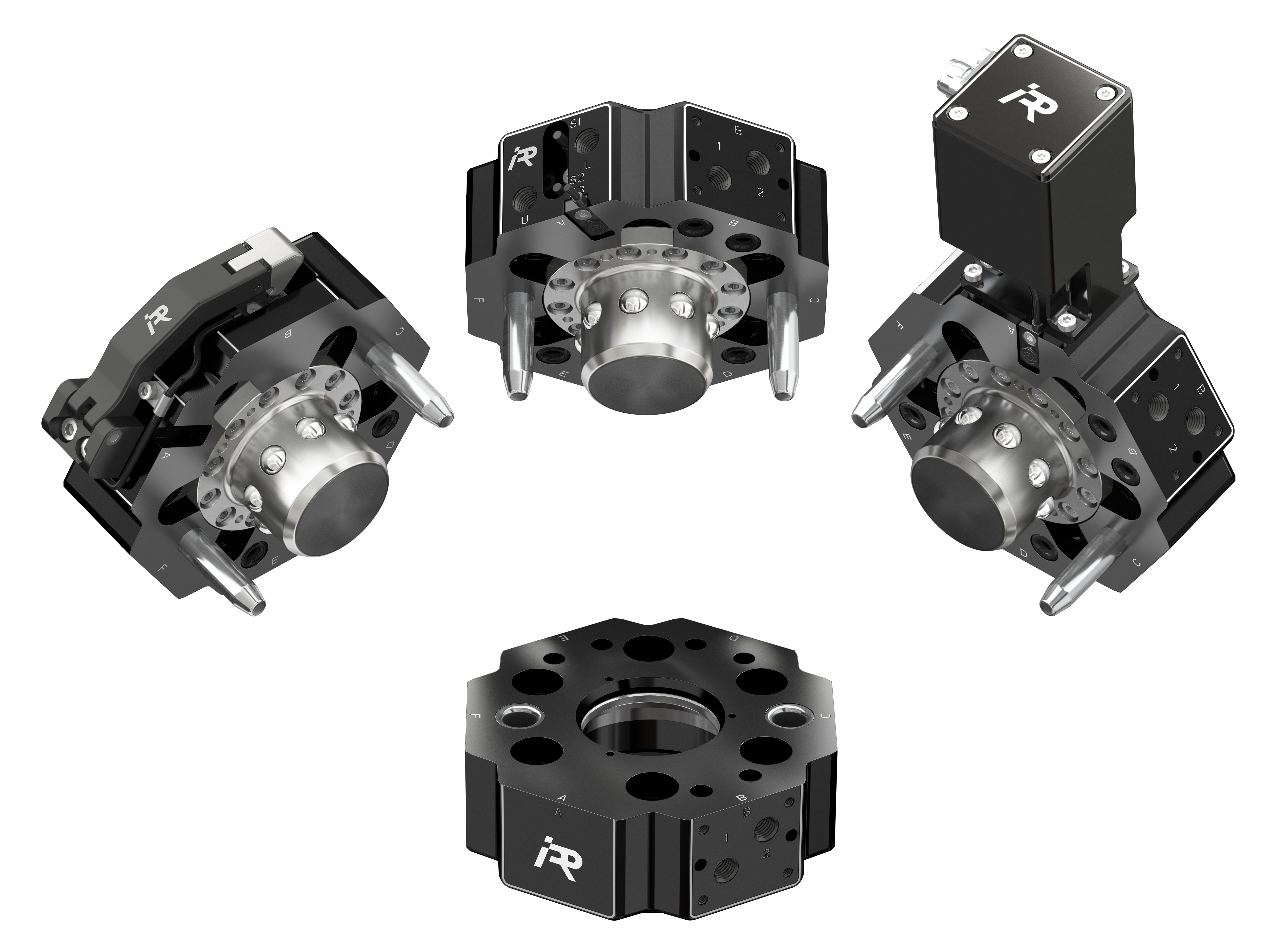

A new addition for smaller applications is IPR's modular TKX tool changer series, where the same tool changer flange fits various robot head locking flanges, whether the locking mechanism is manual, pneumatic, or electromechanical.

- Mounting flange, manual changers: ISO 40 – ISO 125

- Payload, manual changers: 8 – 52 kg

- Mounting flange, automatic changers: ISO 31.5 – ISO 315

- Payload, automatic changers: 10 – 2300 kg

Contact our experts for more information on tool changers.

You can also find more details on the manufacturers' websites via the links below: