Ratkaisut

Paineilmaratkaisut

Teollisen paineilman laajin palveluvalikoima.

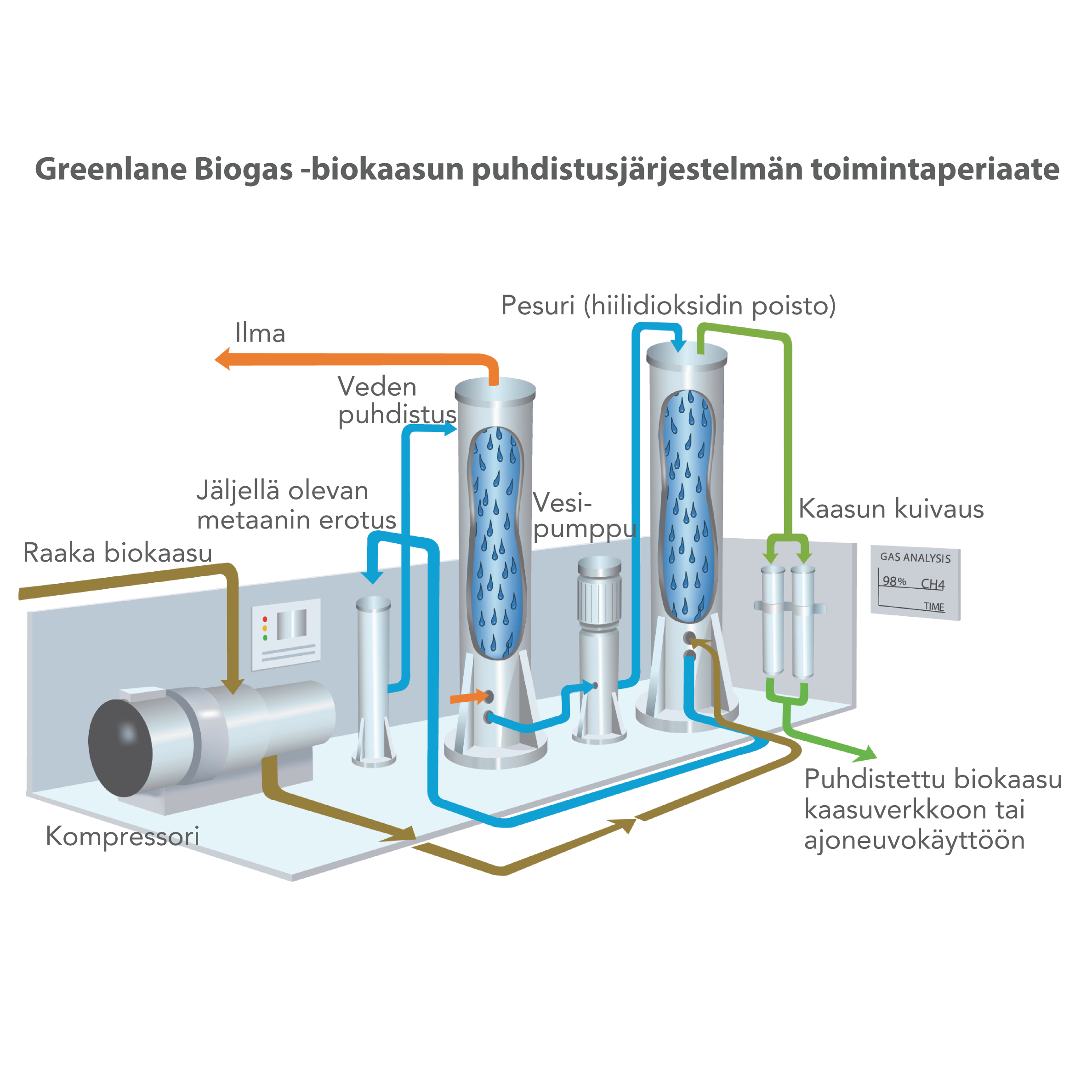

Kaasu- ja energiatekniikan ratkaisut

Energiatehokasta kaasua teollisuuden tarpeisiin.

Automaatioratkaisut

Poista kitkaa tehokkuuden tieltä.

Digitaaliset ratkaisut

Älykkäät ja datalähtöiset ratkaisut teollisuuteen.

Palvelut

Paineilmapalvelut

Kaasu- ja energiatekniikan palvelut

Tuotteet